Date of Issue: March 31, 2001

Hazard Summary

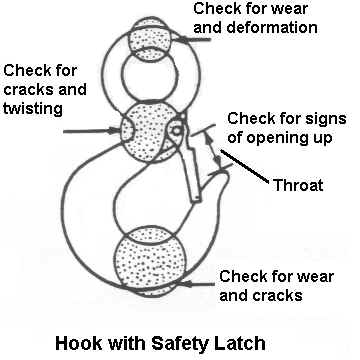

The selection of the appropriate hooks on suspended scaffolds is critical to the safety of personnel. A concern with the use of eye hooks arises when this component of the rigging hardware has a load shift during lifting or maneuvering procedures. It is possible the load may shift to the area of the safety latch on the eye hook. Since safety latches are not normally designed to bear the force of the load, latch failure may occur.

Preventive Measures:

The following preventive measures are suggested:

- components should be reviewed to ensure they are adequate for the work and are in adequate condition

- the appropriate hook should be selected for the work to be performed. The hook should only be subjected to loading in accordance with the manufacturer’s recommendation (side or back loading may not be permitted)

- where a hook is equipped with a safety latch, the safety latch should not be subjected to loading unless it is specifically designed by the manufacturer to carry the weight of the load

- use of a hook with a safety latch does not preclude the inadvertent detachment of a load from the hook; proper hook engagement is required in all cases

- personnel on suspended staging or scaffolding need to be trained in the use of, and equipped with, fall arrest equipment.

Note:

Employers must consider the Occupational Safety General Regulations, Section 80 “Rigging Hardware”. This requires the employer to ensure that rigging hardware is constructed, installed, operated, inspected and maintained in accordance with the following standards: ASME B30.9-1996, “Slings”; ASME B30.10-1999, “Hooks”; and ASME B30.20-1999, “Below-the-Hook Lifting Devices”. These standards may be purchased at http://catalog.asme.org/

In addition the employer must consider the Fall Protection and Scaffolding Regulations, Section 30 “Suspended Scaffolds”.